Tel : 0086-13928981667

Fax : +86-20-28342209

E-mail : humanmech@hotmail.com

Postcode : 510000

Address :Industrial District, Baihedong Road, Liwan District, Guangzhou, China

Product Description

★ Measurement of high precision, stable performance, LCD screen, operation is extremely simple;

★ Measurement of high precision, stable performance, LCD screen, operation is extremely simple;

★ double helix feed is applicable to a variety of different powder weight of packaging;

★ equipped with dust removal system greatly improve the working environment;

★ control computer using Motorola technology, a drop automatically correct, the ultra-poor alarm, fault of their own, can store a variety of production formula, and other functions;

★ number of packaging, packaging of automatic statistics, printouts and data networking communications;

★ table can be received with the conveyor, a machine Fengkou-use, high efficiency;

★ imported pneumatic implementing agencies, reliable, simple maintenance.

Structure

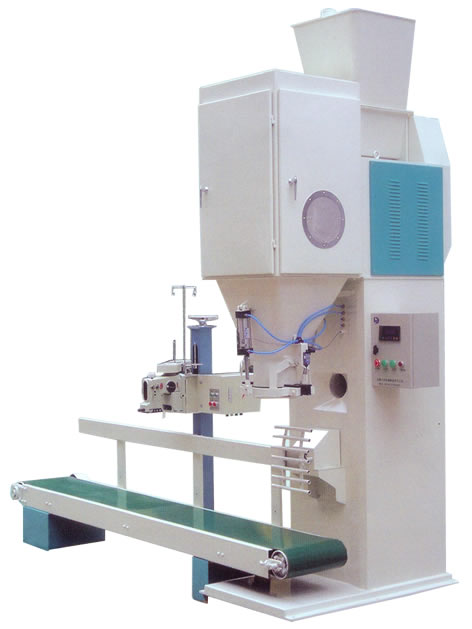

★ The aircraft from the main reservoir hopper, feeding, measuring devices, unloading bucket, dust removal system, computer-controlled, pneumatic control, conveyor, Fengkou and other components.

Application

★ Applicable for automatic weighing and quantritative packing of wheat powder starch and other powder material of foodstuff chemica industry light industry & pharmacy etc.

Product Specification

|

Model |

LCS-10a-DLZ |

LCS-25a-DLZ |

LCS-50a-DLZ |

|

Range |

2-10kg |

10-25kg |

25-50kg |

|

Accuracy |

0.2% |

0.2% |

0.2% |

|

Speed |

150-250 Packe/h |

150-220 Packe/h |

150-180 Packe/h |

|

Power |

380/220v 50hz |

||

|

Gas Consumption |

0.4mpa-0.5mpa |

||

|

Power |

1.1kw+0.75w×2+0.55kw |

||

★ Bag material, shape, size (provided it is the best kind); In order to facilitate better cooperation, special materials please provide:

★ of natural materials (preferably by the provision of samples); A name, B bulk density, C particle size, D moisture content, E mobility, F other characteristics (such as corrosion, etc.);

★ filling material (kg / RB);

★ requirements of the productive capacity;

★ packaging accuracy