Tel : 0086-13928981667

Fax : +86-20-28342209

E-mail : humanmech@hotmail.com

Postcode : 510000

Address :Industrial District, Baihedong Road, Liwan District, Guangzhou, China

Product Description

1、Using Three rows of chain, Smooth operation, Low noise, Long life;

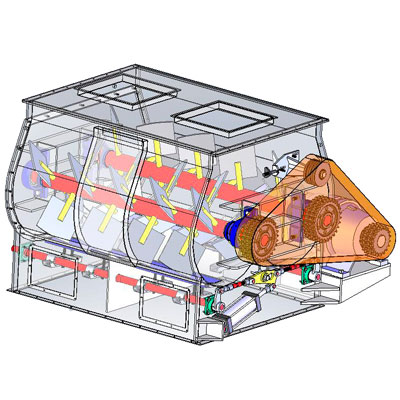

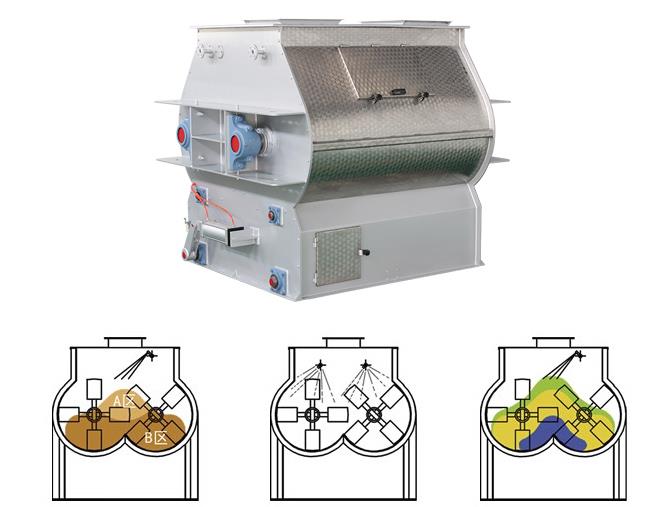

2、Design bigger Mixing chamber, Biaxial blade rotor, Good mixing effect.At the top of the spray system, effectively improve the liquid atomization effect, prevent the cluster;

3、With short mixing time (30~90S/batch ), The mixed uniformity CV≤5%;

4、Total length type of double open the door, big Angle of opening door, Quick discharge, Less remain;

5、Special shaft end and the door sealing structure, Good sealing to ensure no leakage material;

6、It is widely used in a mixture of powder, granule, flake, block material of feed, food,chemical, pharmaceutical and

other industries.

Product Specification

|

Model |

Volume(m3) |

Capacity/batch(kg) |

Mixing Time(s) |

Homogeneity (CV≤5%) |

Power(kw) |

|

SHSJ0.2 |

0.2 |

100 |

30-120s (can be adjusted according to different raw materials)

|

5 |

2.2 |

|

SHSJ0.5 |

0.5 |

250 |

5 |

5.5 |

|

|

SHSJ1.0 |

1.0 |

500 |

5 |

11 |

|

|

SHSJ2.0 |

2.0 |

1000 |

5 |

18.5 |

|

|

SHSJ3.0 |

3.0 |

1500 |

5 |

22 |

|

|

SHSJ4.0 |

4.0 |

2000 |

5 |

30 |

|

|

SHSJ6.0 |

6.0 |

3000 |

5 |

37 |

|

|

SHSJ8.0 |

8.0 |

4000 |

5 |

45 |

Feature of Double-shaft poulty feed mixing

1. High homogeneity

International patent double-circle rotor design, inside and outside doublecircle paddle design, reinforcing convection, shearing, and mixing effects.Mixing homogeneity is up to 97.7%

2. No residues

Adjustable gap between paddle and casing, ensuring extremely low residue ratio, avoiding materials cross contamination;

fully open discharging gate, mixed materials are discharged completely in no time, no

residue.

3. Zero leakage

Discharging gate is sealed with rubber air bag,realizing zero leakage;

At the shaft ends, the packing seal is specially designed to ensure zero leakage.

4. Human friendly

The large access door in reasonable design, ease of cleaning and time saving;

Elevating type liquid addition device "air atomization" contributes to high-precise addition,which ensures homogenous mixing without generating any agglomeration.

Why choose us?

1.Experienced feed pellet line related supplier for over 15 years.

2.Professional sales and engineers team for your service.

3.All of the products have approved CE&ISO9001&SGS certifications

4.Use most up-to-date CNC Machine Center to ensure the quality standards.

5.Every regular customer likes our products/service with great satisfaction.